| Business Type | Manufacturer, Exporter, Supplier |

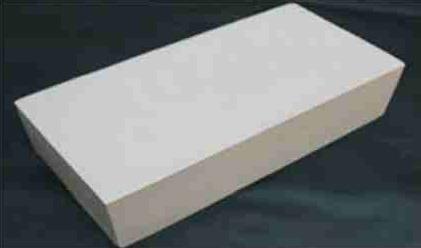

| Product Name | Acid Resistant Bricks |

| Feature | Chemicals process industries,Steel mills Electrolytic plants Oil refineries,Rayon mills |

| Brand Name | GLOBE |

| Click to view more | |

Product Details

Condition

Good

Place Of Origin

Mumbai

Min. Order Quantity

As per Client requirement

Payment Terms

T/T

Delivery Time

Depend on Order

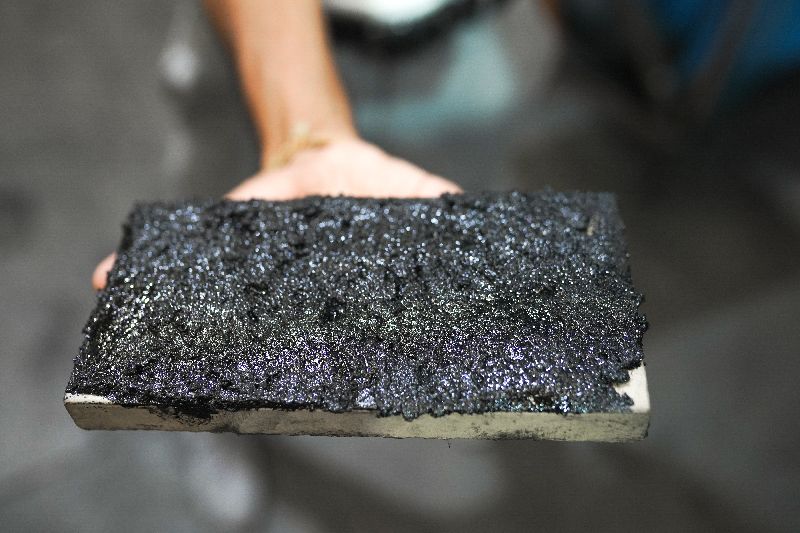

Globe Carbon Industries is the name that is always recommended for prevention from corrosion problem such as acid, alkali and solvent often related to floor, tanks, platforms surface acid pits and other process equipments. To overcome these types of repeated problems, we have developed Acid Resistant Bricks. Our Acid & Alkalis Resistant Bricks and Tiles can withstand the most corrosive chemicals typically prevailing in majority of chemicals industries. We produce Acid Resistant Bricks in different thicknesses, sizes and weights to meet the specific construction requirements. And it is because of our capability to come up with a large variety that we have enlisted ourselves amid the leading Acid Resistant Bricks Manufacturers, Exporters and Suppliers in Maharashtra, India.

Suitable For

Lining Procedure

Suitable For

- Chemicals process industries

- Steel mills

- Electrolytic plants

- Oil refineries

- Rayon mills

- Dyes & pigment plant

- Chlorination plant

- Purely in acidic conditions

Lining Procedure

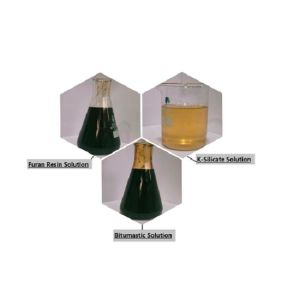

- Total surface preparation is required to clean the surface neat, clean & free fromoil & grease.

- Application of impervious mastic memberance as a primer; to be applied between the surface & brick lining.

- Bedding with K-Silicate / Sodium silicate mortars.

- Potrassium silicate base cement which resists against wide variety of acids & entire range of temperature upto 800oC. Two part mixture, powder to Liquid 3 : 1 ratio.

- Sodium silicate Base cement which resists temperature upto 650oC can be use as bedding materials of A.R. Brick lining. Two part mixture, powder to liquid 3 : 1 ratio.

- Joining will be done with silica furan base cement from top & nearly 5mm deep inside to protect the surface from corrosion. Two part mixture, powder to furan syrup 3 : 1 ratio.

Specifications

| Properties | Results |

| Cold crushing strength | > 700 kg/cm2 |

| Flexural strength | > 100 kg/cm2 |

| Water Absorption | < 2 % |

| Bulk Density | 2.250 kg/ cm2 |

| Chemical composition | AL 203-22-24 % + SIO2-60-65% + Fe2O3-1-2% & Alkalies - 10-12% |

Properties are as per IS 4860 (Class – 1) And Astm C - 279

Looking for "Acid Resistant Bricks" ?

Piece